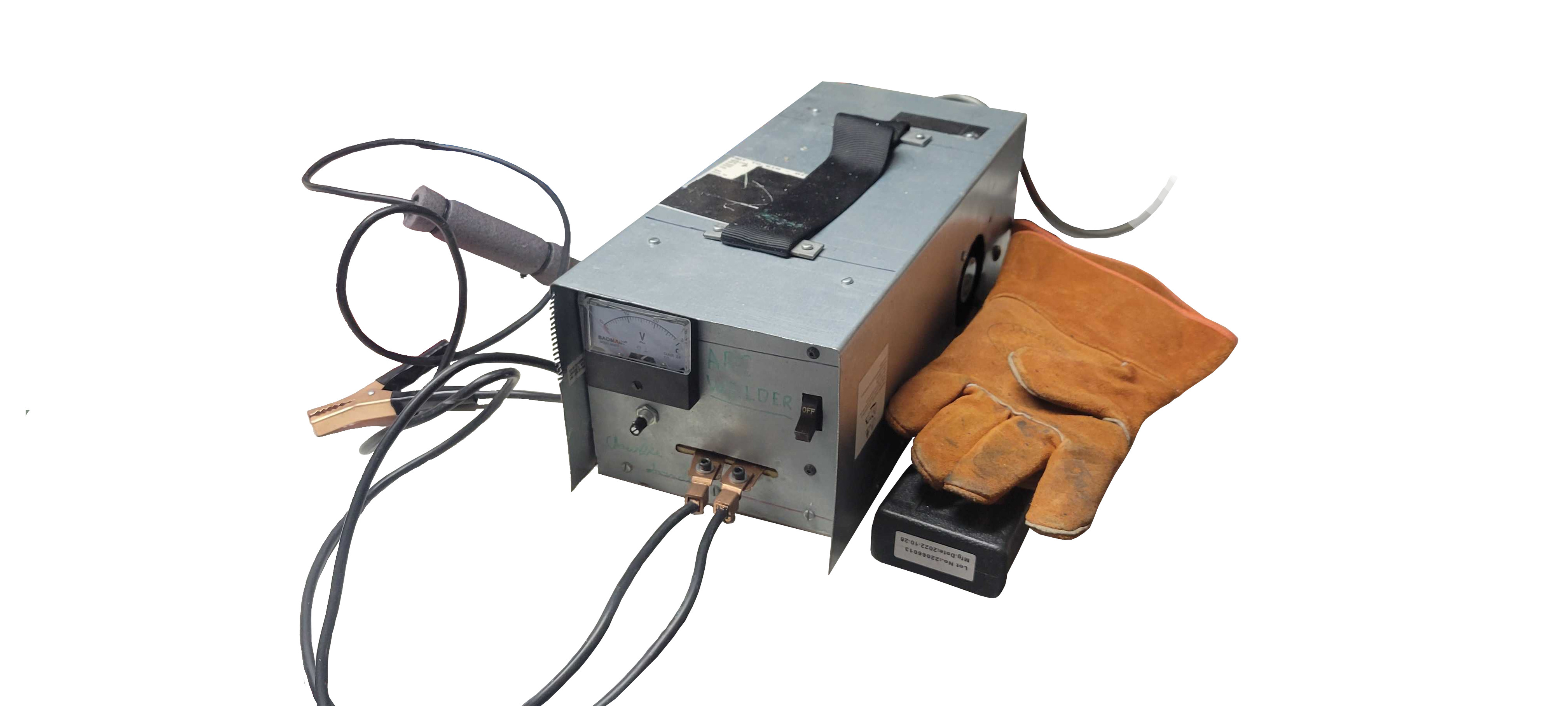

Arc Welder

May 2023

My high school’s engineering class had us create some sort of “upcycled” product. I was looking for a use for two microwave transformers and had seen some others build welders. I needed to do some welding and did not want to buy a machine jumped at the chance to build one myself.

Design Inspiration

I based my design off of similar devices built by other people.

- Mind To Machine’s welder - Sightly more complex DC 120 volt arc welder (taken down)

- Kurt’s Cottage’s welder - Simple 120 volt AC arc welder

- Murat Güney’s welder - Nice looking chassis design

- The King of Random’s welder - Basically the same as Kurt’s welder but in a plastic box

I based the sheet metal design and construction of my device somewhat heavily off of the device built by Murat. The electrical aspects were based off of Kurt’s Cottage’s, Mind To Machine’s and TKOR’s welders.

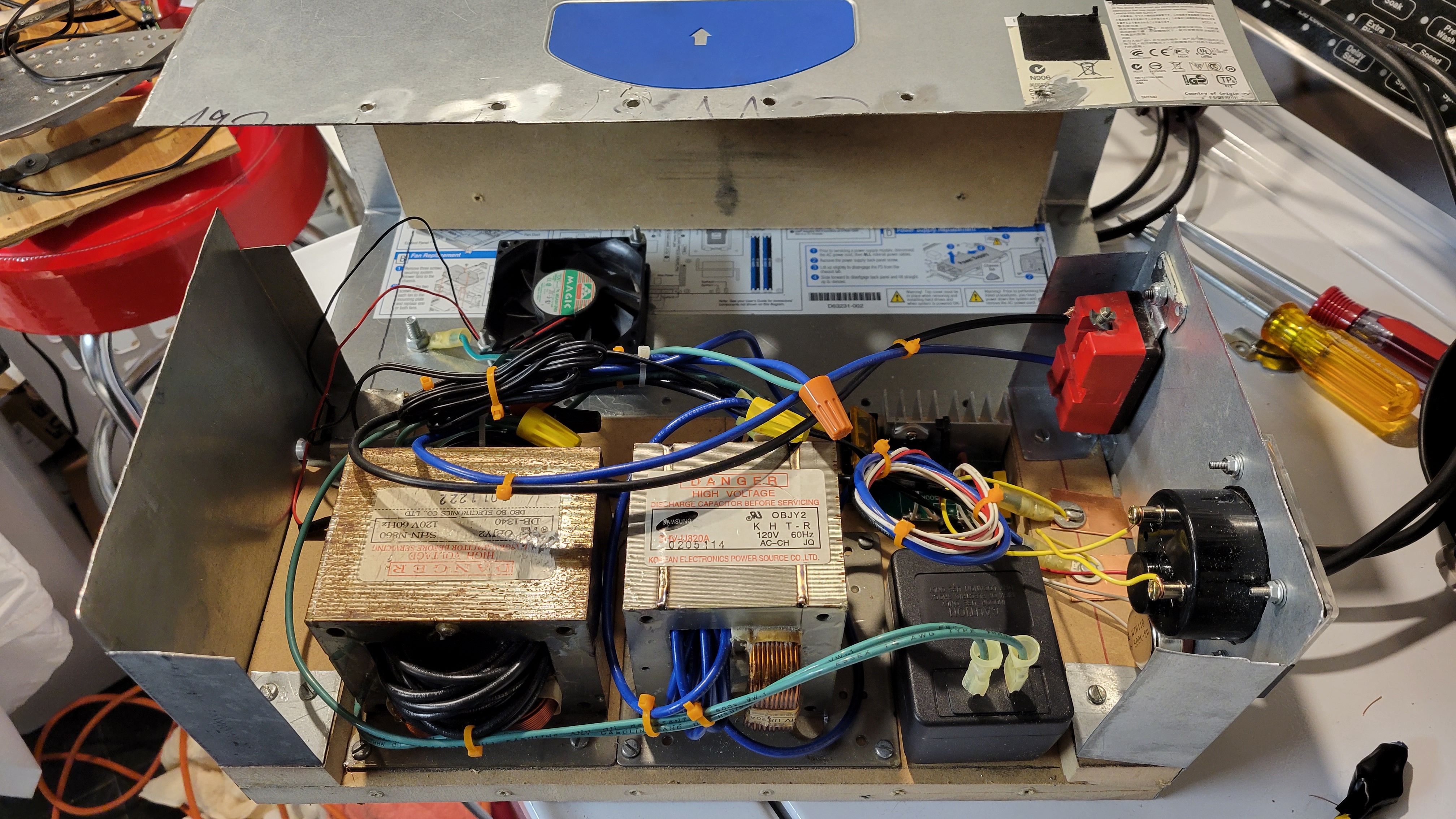

Electrical

The electrical system is very simple, it is just two microwave oven transformers (MOT) with parallel primaries and series secondaries. The primaries are the stock coils built in to the MOTs. I cut out the high voltage secondaries and rewound them with between 20 and 30 wraps of 12 AWG wire. I ran a series 4000 watt light dimmer (which has to be one of the most un-UL-listed parts I have ever seen in my life, but seems to work alright). I also installed a volt meter to show the voltage output of the welder. At max power it emits approximately 35 volts and can probably operate at about 70 amps (although I have no way to measure this). This is enough to weld 3/32 inch welding rods and maybe even 1/8 if you are willing to push it. All told I am rather happy with its performance.

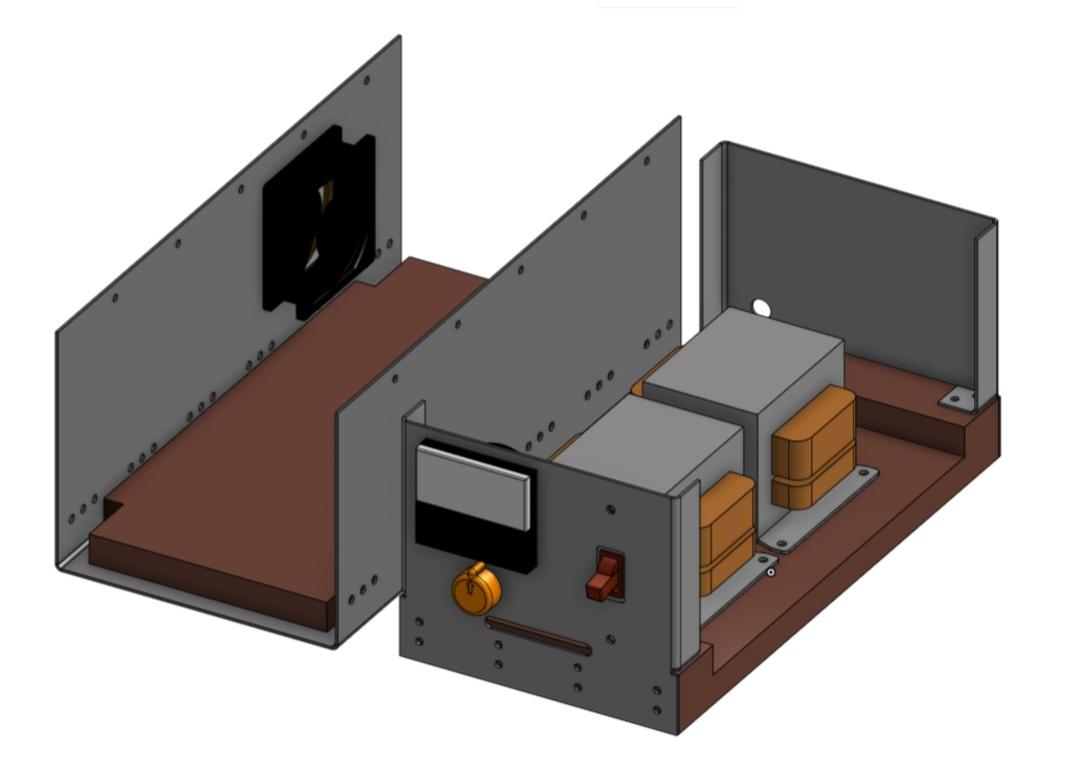

Physical Construction

The main construction of my welder is made up of 1/32nd inch galvanized sheet metal scavenged from old computer chassis and scrap ¾ inch fiber board. Prior to constructing it I modeled the whole thing in CAD to make sure everything would fit well. When I assembled the project everything fit well the first time.

Welding

As mentioned above I have only welded with 3/32nd inch welding rods on this machine. The welds seem to penetrate rather well and are relatively strong. I think the steel will fail before weld.